American Airlines shared performance stats with employees yesterday after “three weeks on the books for the 2019 peak summer travel season [and] 11 1/2 more weeks remaining.”

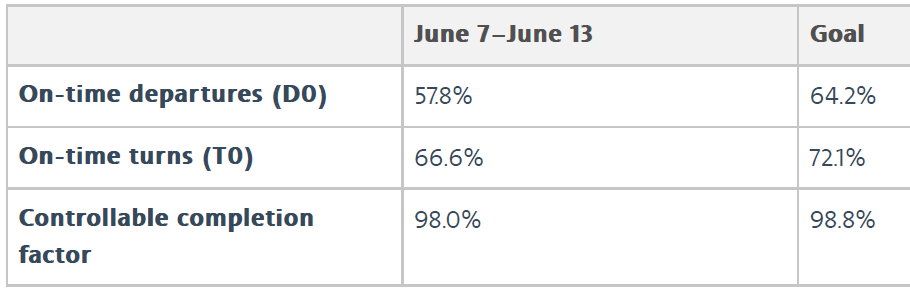

Looking specifically at June 7 – 13, here’s how their performance stacks up for departing exactly on time (“D0”), turning aircraft on time (“T0”), and not cancelling flights for reasons within their control.

Despite a company-wide push for exact on time departures for years and operational changes meant to improve the airline’s reliability they only managed to hit D0 57.8% of the time. That to me is horrible, even if their goal was only 64.2% (‘the soft bigotry of low expectations’).

The battle with American’s mechanics right now has gotten vicious. The airline even took its union to court to get them to stop intentionally slow walking and causing delays. This isn’t just about writing up items unnecessarily, it’s about waiting to write up items until the last minute forcing delays and about taking longer than necessary to complete paperwork too.

American makes excuses, telling employees that they were hurt by “a widespread Rockwell Collins transponder failure that impacted some regional Bombardier CRJ aircraft operated by Mesa, PSA and SkyWest” as well as “severe weather, which resulted in more than 360 departure cancellations over a two-day period at DFW.” However weather cancellations weren’t controllable, and ‘things happen’ is precisely why their goals aren’t 100%.

Notably D0 goals were exceeded in Asia, Europe and South America, and aircraft turn time goals were exceeded in Caribbean and Europe are all above the T-0 goal. In other words, the places least affected by mechanics’ operational sabotage did well and North America fared even worse than the data above suggests.

This issue with mechanics needs to be solved quickly. We’re only about a third of the way into the summer peak schedule. The airline gave mechanics a raise without a new contract, reducing the gap between what they were making before and what they’ll make once a new deal is ratified. That means there’s less pressure on employees to get a deal done, and less on the table to get them to agree to concessions on scope (having non-union workers fix planes) and benefits (moving legacy US Airways mechanics over to the less generous American health plan).

More Passengers Than Ever Waiting to Be Delayed

American needs to keep crews with planes, so that when an aircraft is delayed that doesn’t cascade into delaying more than one downline flight. They also need to increase block times — that’s expensive in the short run, but right now American just needs to stop the spinning. Focus on getting each step along the process right so that planes are able to push back on time and that there’s a gate and staff to meet each aircraft so it arrives on time, too. In other words, D0 isn’t the only metric that matters Delta by the way focuses on A0.

Is there a way we can determine why a flight was canceled? I had a specific flight I really needed on June 9th that was canceled the night before by American. They claim it was because of weather, but I knew this dispute was happening so I wanted to figure out what the real reason was.

Gary would be helpful if you post comparable on-time statistics so we know how AA is stacking up with their competitors to determine how these numbers are.

You make a case for the importance of A0 (arrival) vs D0 (departure) so what are the arrival statistics?

Simple Solution – Pay them.

I have union mechanics where I work, who are well paid. In turn, they are happy and have no problem repairing everything as fast as possible, even when they technically don’t have to.

“I’m on break, but if you really need this looked at ASAP.. I’ll do it now.” is something I’ve heard more then once. It’s quite nice really. It’s a skilled position, and not easily replaceable. These aren’t bag handlers. These are people who can take apart airplane engines, and put them back together again. Simply pay them what they are worth.

D0 = arriving at DFW or ORD 20 minutes early LANDING at a runway on the other side of the airport, taxiing and still waiting 15 minutes for a GATE to open up.

A0 is better

The premise of your post is entirely wrong: it should be “Data Shows How Badly Mechanics WERE Hurting American Airlines Reliability.” The court’s order last Friday is a game-changer, at least for the summer. The mechanics won’t dare engage in slowdown tactics now because, historically, airline labor unions have been fined millions of dollars (including individual fines) for violating a no-slowdown court order. I would think you have enough “expertise” in this industry to know that.

As far as your stats go, I think you picked the least compelling ones — or at least presented them without context. How close to their on-time “goal” was AA BEFORE June 7? Without knowing this, your chart tells us nothing.

That said, there were certainly more mechanical delays in late May/early June than previously. And it seems like certain flights were particularly targeted; especially long-haul international. Many of the European flights all seemed to be routinely delayed and cancelled. To my knowledge, that has now — magically — stopped.

Your post also “dismisses” weather concerns, but those are real — and on-going. AA’s largest hub at DFW has had horrific weather the past several weeks — the worst I can recall. It was bad there again today — the most cancellations at any airport in the world. AA’s reliability isn’t going to be competitive until the weather at DFW gets better.

All that said, there does seem to be something structurally “wrong” with AA’s operations — at least compared to their competitors. Delta, with a much older fleet and far fewer mechanics on the payroll, rarely cancels flights except in the most egregious weather conditions. Why can’t AA be as reliable as Delta? That’s a real question that thought leaders should be asking.

@Mangar — Your view is very simplistic. AA actually wants to pay its mechanics far MORE than they are “worth.” They want to overpay their employees and give them ridiculous perks like allowing them to stay in their current stations even if the workload doesn’t justify it. The union, however, doesn’t want this.

Why? Because AA has far more mechanics than its competitors. And AA doesn’t want to replace unneeded workers when they retire. The union wants these workers replaced — it doesn’t want AA to do its mechanical work more efficiently and, God forbid, with workers who aren’t on AA’s payroll. That’s the biggest problem in their negotiations. That’s not an easy issue to solve but, inevitably, it will be solved by both sides giving a little.

Why must a employer take employees to court? Why must to dispute last 3-4 years? This dispute should be resolved at the bargaining table (even if it means 24/7) not in the courts!

@John C — If you want to know the answer to your question, study the history of the Railway Labor Act. It’s a weird beast. What’s going on at AA with its mechanics is not unusual at all in the airline industry. Be glad that the rest of the US economy isn’t run this way!

Here’s an enormously insightful report on AA’s lawsuit against the mechanics. It draws one inescapable conclusion: the mechanics will NOT be slowing down AA’s operations this summer (or their leaders may be going to jail).

https://www.middleagemiles.com/2019/06/19/american-airlines-vs-mechanics-union-a-breakdown-and-perspectives-from-a-texas-trial-lawyer/

Remember Northwest Airlines? They were out of Egan Minnesota, my cousin was a lead mechanic a certificated power plant mechanic. Do you know what Northwest did? Moved his job to China. Huh (?) I can hear you say, how did they do that?

Simple, every year every airplane needs a complete overhaul, they used to to the yearly overhauls in Minnesota, then management decided, “Hey we can fly the planes to China and get the annual overhaul done much much cheaper.” I woner where American Airlines gets their big annual plane overhauls done? I bet the mechanics at AA know where.

Thank you chopsticks , from the law blog you linked to:

AA and the Union have been engaged in negotiations for a new labor agreement (a Collective Bargaining Agreement, or CBA), since December 2015. Having not reached an agreement in almost 3 years, the parties turned to mediation through the National Mediation Board. Mediation is a process of further settlement discussions, with a trained neutral third party acting as a go-between, or mediator, to help facilitate agreement. There were several settlement meetings as part of the mediation process. The most recent (and last-scheduled) meeting occurred in late April 2019 and ended without agreement.

According to the Union, the major sticking points to the CBA negotiation have been (a) the extent to which AA will have the ability to contract maintenance work out to vendors (and thereby reduce the number of maintenance jobs at AA); and (b) health care.

[see my prior comment above re: China]

@OlderWoman — Crankyflier also has some recent commentary about the mechanics dispute. One problem AA has in this dispute is that it’s actually dealing with two mechanics unions each of which, apparently, has different goals!

“Outsourcing” is definitely an issue in these negotiations, but not necessarily to the extent that you would think. There doesn’t seem to be any great desire on management’s part to ship lots of work overseas. But there does seem to be some desire to do the mechanical work more efficiently. Seems like a solvable problem. Eventually. For flyers, the good news is that the immediate problem — cancelled flights due to a mechanics slowdown — would seem to be resolved.

Well there it is, the solution to what will really make American successful, summed up in the few sentences of the last paragraph.

Because Scheduling crew with equipment seems to be the soup de jour lately, I must query one thing: If you’re taking that plane and it has a two hour delay, would you rather keep the two hour delay or have a new crew that can get you out with less of a delay and perhaps even on time?

Keep in mind while you ponder the answer, if you choose to wait for the late-coming crew, that delay, depending on how long the crew has been on duty, may cause the crew to Time out for the day and your flight potentially could cancel.

https://www.forbes.com/sites/tedreed/2018/04/06/amount-of-outsourced-offshore-airline-maintenance-work-has-risen-report-says/

@Cloudface — This Skift article has another good summary of the AA mechanics dispute. AA wants to do things like have AA mechanics in Brazil work on their aircraft during the considerable downtime those airplanes have in Sao Paulo based on scheduling issues (the planes fly to deep South America at night, and sit in Brazil during the day). The union complains that these jobs should stay in America. Does this make any sense? Of course not. And the idea that the Brazilian mechanics can’t do good work is stupid. We all fly on a lot of Brazilian-made airplanes (Embraer)!

https://skift.com/2019/06/18/american-airlines-union-dispute-more-disruptive-than-737-max-grounding/?utm_content=94401162&utm_medium=social&utm_source=twitter&hss_channel=tw-374822255