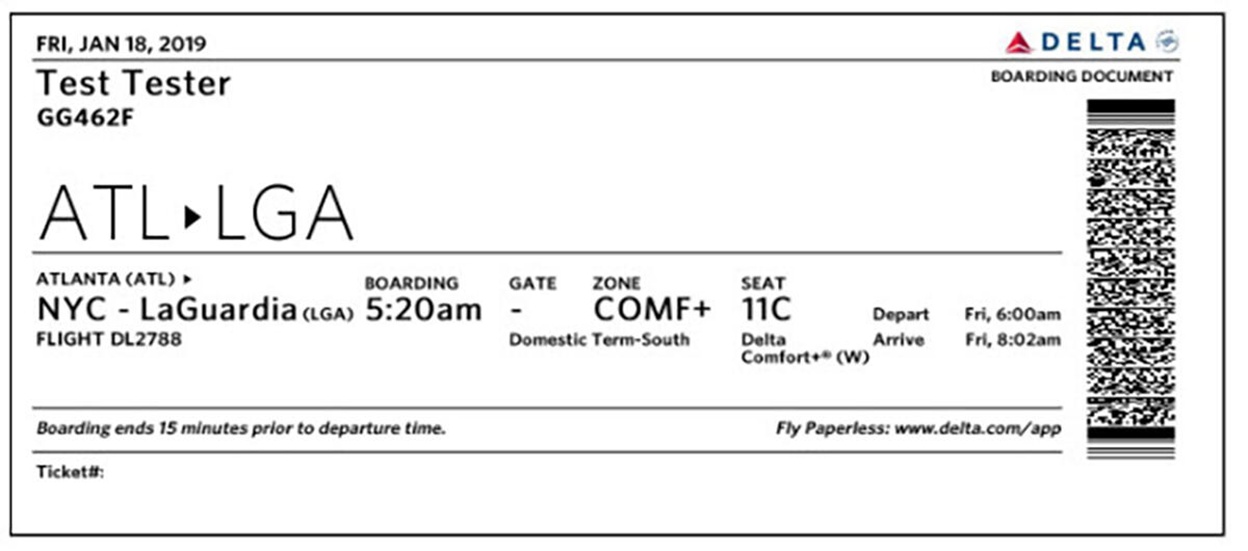

Delta has stopped printing two bar codes on boarding passes. They now print a single 2-D boarding pass barcode on paper printouts, and they’ve removed the vertical 1-D code that used to live on the right edge. Delta agents agents say the reason is to ‘save ink’ when printing boarding passes. Yet according to a Delta Air Lines spokesperson,

Delta began making this minor change to our printed boarding passes this summer to increase compatibility with more airport barcode scanners around the world.

VAL KILMER'S BOARDING PASS??? (2009) pic.twitter.com/liqpHVbqNS

— Howl Kilmer (@HowlKilmer) November 18, 2025

Both explanations are true.

The airline industry has been migrating to IATA’s Bar-Coded Boarding Pass (BCBP) standard, which uses a 2-D symbology (PDF417 for printed passes and Aztec/QR/DataMatrix for mobile) so a single barcode carries everything the airline and airport systems need.

That vertical barcode was a legacy, 1-D (linear) code. It can be vendor-specific and different for each airline. It’s been kept around for backward compatibility with older scanners and legacy processes.

You would think having the extra barcode would be innocuous. However barcode imagers will scan whatever readable symbology they find first, and a stray 1-D code near the main code can:

- be read instead of the more desired code, handing back useless data to the 2-D system, or

- Infringe the required “quiet zone” around the 2-D symbol and reduce scan reliability.

Both cause intermittent failures at check-in, security, or the gate. A scanner that decodes a linear code when the system expects a BCBP string will look broken even though the boarding pass itself is fine.

Delta doesn’t think they need the older code for compatibility anymore, to deal with legacy systems. That’s great. IATA also explicitly sells the 2-D encoding as a cost-savings on printers, mag stripe hardware, etc.

The incremental cost of one extra 1D barcode on thermal stock is tiny per pass, but across tens of millions of boarding passes a year, it’s not literally zero: more printed area, more wear on print heads, slightly longer print time. At scale that’s real money. Remember American Airlines saved $40,000 cutting a single olive from first class salads (that’s over $100,000 in today’s dollars).

Front line agents may hear both compatibility and saving supplies, which means greener and less waste (always and everywhere and especially at Delta code for cost cutting) and repeat the cost-cutting piece to customer. But both elements are true parts of the story here.

It’s always Delta.

Rear question: How dis affec Derta’s Brack Friday Bunduru?

To save ink? There’s no ink. Boarding passes (and baggage tags) are thermal printed, on heat sensitive paper.

I genuinely do not care about the code. It’s fascinating, but please picture a giant shrug. More compatibility seems good, but what the hell do I know. Anyway.

I’m so sorry, but the cost-savings math is bad.

That titular single olive is worth exponentially more than the tiny extra bit of energy required to heat an square centimeter of the exact same size thermal paper. There’s maybe a breath more processing power and maybe it takes a nanosecond longer to get the pass?

So fleetwide the olive thing saved $100k in 2025 dollars? In total savings. I’ve had too much gravy to do math, but my tryptophan added brain figures eliminating the code therefore is equivalent to … ten grand? Across the entire organization? Cash dollars. And that feels extremely generous? Even across billions of passes per year

That’s weirdly not worth even mentioning the cost savings? I mean, I guess, yes it’s >$0, so it’s not untrue. Just weird.

Ink is the simplified explanation of gate agents which I take to mean as ‘lowers cost’ which is something IATA expressly promotes

Printing in 1-D???

On a piece of paper

Unlikely

Marcelo OK, I assume you are a child, so I will help. A one-dimension code is like the bar code on all your grocery items. A two-dimension code is like a QR code. Ask your oldest sibling.

@This comes to mind — Thanks professor!

As someone who used to work in IT for Delta, the typical printer they use is consider disposable. It’s under whatever arbitrary value that it’s not worth sending back to their main facility for repair. Once it’s incapable of printing readable codes, we just sent them to recycling. Maybe they figured out they can extend the life by a margin to make it worthwhile.